MAGNIFY the EFFICIENCY

& ROI of H2 Fuel Cell Ownership

Plus Making Inexpensive Hydrogen

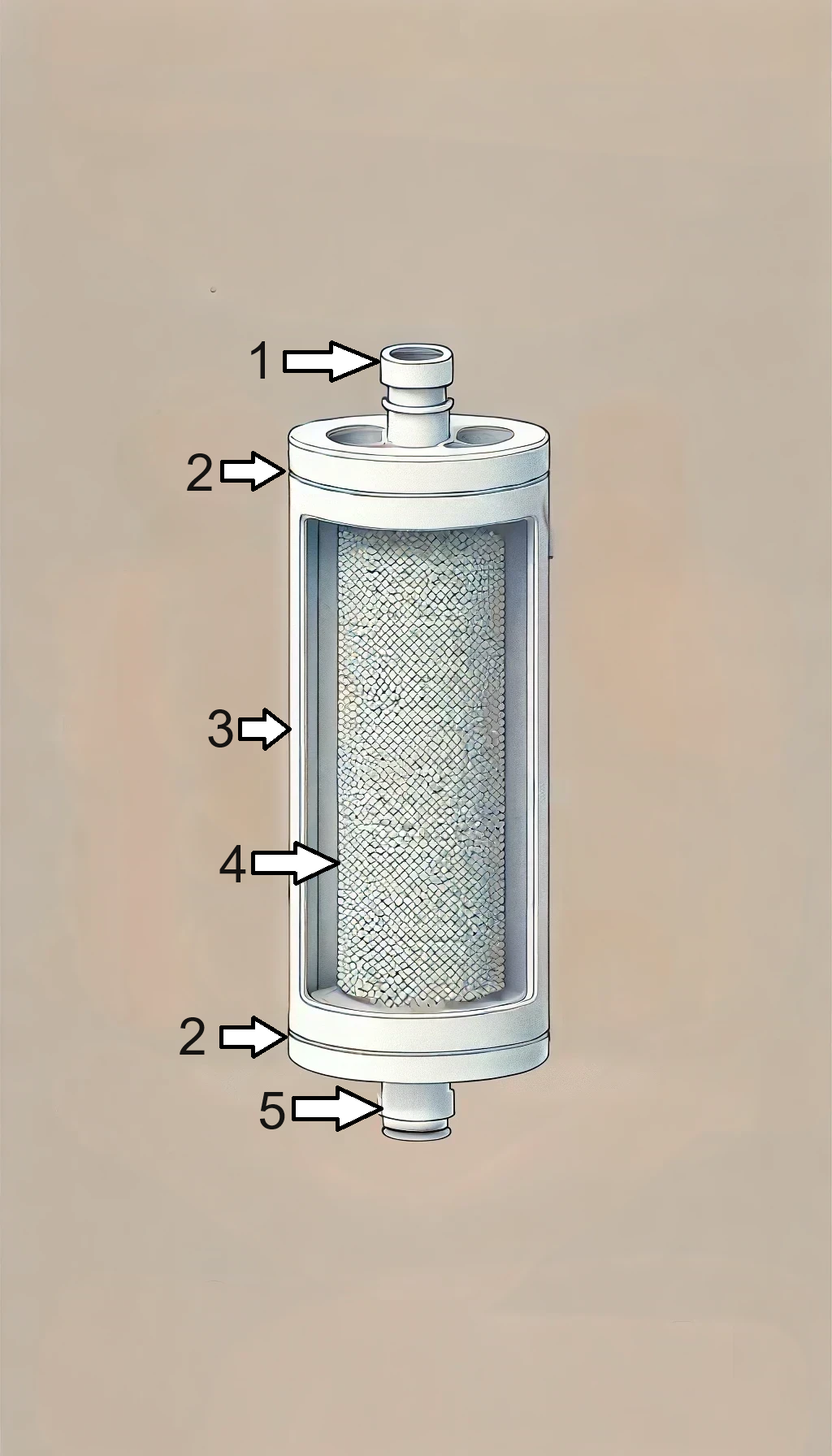

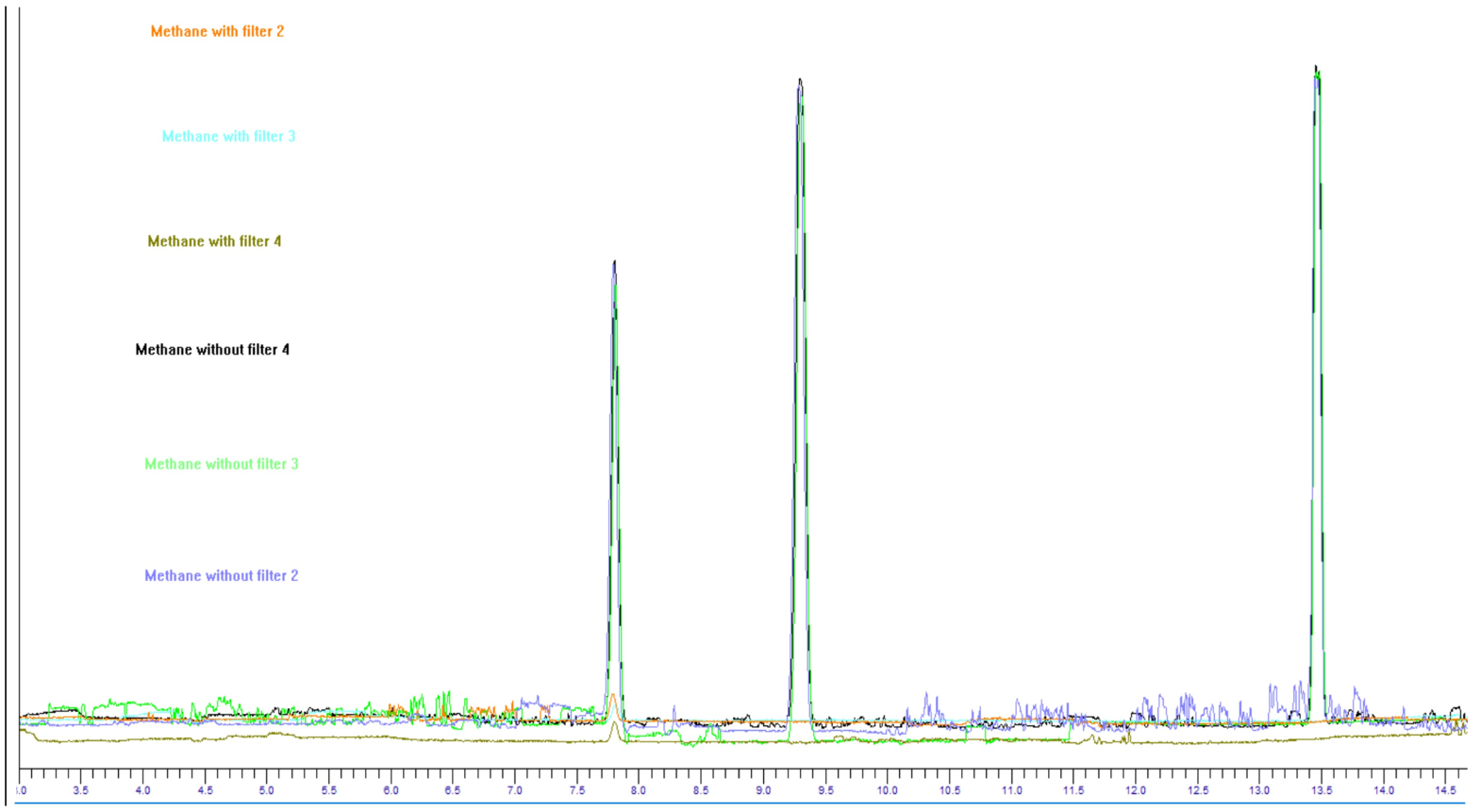

Standard H2 has developed a revolutionary, proprietary process for producing the cleanest hydrogen imaginable with H2S below 200 ppt to prevent damage to the critically important H2 Fuel Cell Catalyst. Our proprietary products and process can even clean the hydrogen produced by electrolysis of water which is not as clean as you think or your fuel cells in your forklifts wouldn't fail after only a few years.